HEATING AND COOLING

SOLUTIONS TAILORED FOR YOU

COMPANY

Founded in 1970, Frigosystem remains focused on the design, manufacture and sale of industrial chillers and temperature controllers, with a long experience in high accuracy systems.

The wide range of the products permits to satisfy all specific demands of both small and big industry: Frigosystem can structure their offer with tailor-made plants and proposals, always oriented to efficiency and energy saving.

The vocation to innovation, the constant research in technologies and marketing, the application of professional ethics support Frigosystem in its continued growth and in the consolidated cooperation with world renowned OEMs. The company is today present in the world with a wide sales and service network.

Since 2024, Frigosystem has a partnership with PTA UK Ltd. for the marketing, sales, installation and service of cooling systems in the UK territory.

PRODUCTS

RACA-C

Versatile air-cooled chillers available in multiple configurations. Flexible, efficient, and compact, with specialized versions for tropical climates, oil cooling, or very low temperatures.

RACA PLUS ENERGY (RPE)

High-efficiency chillers with SEPR values beyond ErP 2021 standards. Compact, versatile, and sustainable, they integrate free cooling and heat recovery for up to 90% energy savings.

RACA HEAVY DUTY (RHD)

Heavy-duty screw compressor chillers, robust and reliable for demanding industrial environments. Designed for wide capacities and extreme climates, with optional free cooling and heat recovery.

I-RES

Magnetic levitation chillers delivering top seasonal efficiency (SEPR up to 12.04). Oil-free compressors, flooded evaporators, and Industry 4.0 connectivity ensure maximum performance with minimal environmental impact.

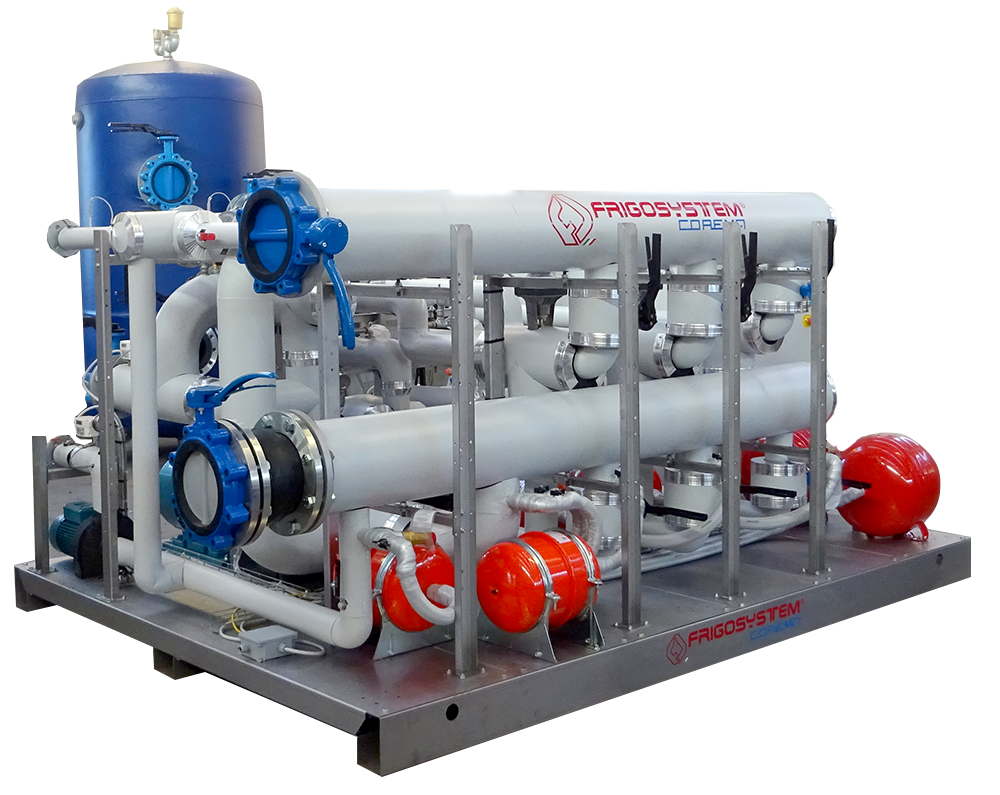

Pumping Systems

Frigosystem Corema’s SKID pumping units are complex hydraulic intermediation systems designed to manage fluid circulation between chilled water production plants and utilities. Each SKID is engineered with precision to meet specific flow rates, temperatures, and pressure requirements of the installation site. With high flexibility and customization, SKID units provide the perfect integration for industrial cooling and heating processes, ensuring efficiency, reliability, and long-term durability.

KBFC - Modular Water/Air Exchanger

Flexible, stackable water/air units designed for minimal footprint and stable operation.

KITE DEX - Advanced Cooling for AIR Ring & IBC

High-efficiency cooling system with free cooling and precision control.

KITE - All-in-One Compact Solution

Integrated mono-block system combining ring air cooling, IBC, and water thermoregulation.

DC - Dry Coolers

The DRY COOLERS have the advantage of being able to operate without water consumption eliminating all the typical problems of traditional cooling towers because the system works in closed circuit, without losing control in efficiency. All DC systems can be included into existing systems and controlled by a new generation microprocessor that also allows the insertion of a modulating three-way valve on the system for further savings.

ACE - Adiabatic Cooling Energy

The DRY & ADIABATIC division includes Frigosystem solutions for industrial cooling, focusing on saving energy, being eco-friendly, and reducing consumption. The systems are made to be reliable, easy to connect with other equipment, and to work well over time, even in tough conditions. This line shows the company’s promise to use new and green technologies that can meet the needs of different industries with solutions that are easy to customize and use.

HC – Heating & Cooling Thermorefrigerator

All-in-one solution that integrates cooling and thermoregulation in a single compact unit, reducing space, energy, and costs.

TMO – Oil Thermoregulators

High-temperature thermoregulation with diathermic oil up to +350°C, designed for demanding and continuous processes.

TRW – Water Thermoregulators

Compact and versatile water units ensuring precise temperature control up to +180°C, adaptable to multiple industries.

ABOUT THAILAND

CASE STUDIES

Tank Cooling Project – Injection Moulding

Requirement:

We were approached to look at a project where they where looking to replace an old 150kW chiller that was connected to a tank for the tooling factory cooling, they wanted this changed over with minimal disruption to minimize factory downtime due to production demands. The customer was looking for reliability, variable loading and ease of use, along with value for money.

Solution:

We supplied one of our RPE units, fitted with an integral pump, which made it easier for the customer at the changeover. The customer liked that the chiller had two compressors in the selected model to achieve partial loading when required. This along with variable speed fans, gave them the energy saving they desired.

Extrusion Bath and Pellatizer Project - Extrusion

Requirement:

To supply a self contained 200kW air cooled chiller with an integral pump and tank, so the customer could connect direct into the pipework to cool their extrusion bath heat exchangers and pellatizing line.

Solution:

We supplied one of our energy efficent RPE units, fitted with a single integral pump and tank, which made it easier for the customer’s installation as they going to move this to aonther location shortly and will not have the issues of moving external pumps, tanks and control systems.

Replacement Chiller – Injection Moulding

Requirement:

We where contacted by a customer who required a quick turn-around as their old self-contained chiller with it’s own pump and tank had got to the point it unreliable and wasn’t cost effective to repair, so they made the decision to contact suppliers they knew for a replacement.

Solution:

Once the duty was confirmed and agreed with the customer, we proposed a self-contained RPE unit with it’s own pump and tank. We had this in stock and we were able to deliver this to the customer straight from stock. The customer was able to install and commission the chiller easily themselves due to the easy plug and play operation of the unit.

INSTALLATIONS

PUMPS & TANKS

We can supply and manufacture from a simple single pump and tank design to complex multiple pump and tank systems for linking between the chilled water production plants and process.

Each pump tank module or skid design, responds to specific requirements, like flow and temperatures, as well as pressure losses related to the plant design of each installation.

We can incorporate PLC control systems giving control of the whole system, with the ability to communicate with the local on-site engineers.

Water and Energy Saving

To achieve the best from energy saving, this starts with a detailed assessment of your existing systems. From there, we can discuss and create a no obligation system proposal that details realistic energy and cost-saving forecasts, and accurate return on investment.

If you feel like your production could benefit from an energy saving analysis, don’t hesitate to contact us (info@frigosystem-thailand.com) or call us today on +66 2 517 1699 to arrange a free energy survey, and to discuss how we can help you.

PIPEWORK

We can supply and install process pipework in all sizes and materials for process cooling systems, thermal oil systems, compressed air and material conveying.

- Welded Stainless Steel

- Crimped Stainless Steel

- Gavlanised / Rolled and Threaded

- ABS and PVC

- Aluminum Tubing

VIDEO

CONTACTS

Via John Fitzgerald Kennedy, 240

21042, Caronno Pertusella (VA)

info@frigosystem.it

+39 029658610